Raise Your Devices: Discover Premium Komatsu Undercarriage Parts Solutions

Raise Your Devices: Discover Premium Komatsu Undercarriage Parts Solutions

Blog Article

Efficient Solutions: Undercarriage Components for Heavy Equipment

Quality undercarriage components play a significant duty in making sure the smooth procedure and longevity of hefty equipment. In this conversation, we will check out the significance of investing in superior undercarriage parts, typical wear obstacles encountered by hefty equipment drivers, the advantages of prompt substitutes, guidelines for selecting reputable vendors, and essential maintenance suggestions to expand the lifespan of undercarriage parts.

Significance of High Quality Undercarriage Components

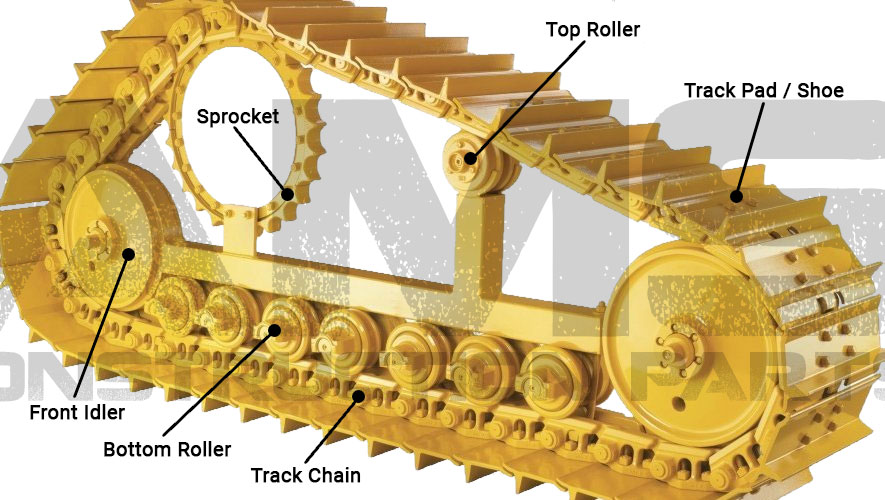

Quality undercarriage parts are vital components in making certain the durability and efficiency of hefty equipment. The undercarriage of tools such as excavators, bulldozers, and track loaders plays a vital role in supporting the machine's weight, offering stability on numerous terrains, and soaking up the impact of unequal surface areas. By buying premium undercarriage parts, drivers can considerably extend the lifespan of their machinery and reduce the danger of unforeseen malfunctions.

One trick benefit of making use of top quality undercarriage components is the enhancement of general equipment efficiency. Resilient tracks, idlers, rollers, and gears decrease rubbing and make sure smoother activity, ultimately causing enhanced productivity and efficiency on task sites. Furthermore, reputable undercarriage components minimize downtime for repair and maintenance, enabling operators to maximize their functional hours and task target dates.

Usual Undercarriage Put On Issues

Advantages of Timely Replacement

One secret advantage of timely undercarriage part substitute is boosted device uptime. By replacing worn parts before they stop working, the threat of unanticipated breakdowns is lessened, minimizing downtime for repairs and upkeep. This positive approach not only keeps the heavy equipment functional however additionally prevents possible damages to other parts that could arise from a falling short undercarriage.

Moreover, changing undercarriage components immediately can enhance general efficiency. Investing in prompt undercarriage component substitute is a proactive method that pays off in terms of enhanced effectiveness and reduced functional expenses.

Choosing the Right Undercarriage Provider

Selecting the proper undercarriage distributor is an essential decision that dramatically influences the efficiency and maintenance of hefty machinery. When choosing a provider for undercarriage parts, a number of elements have to be considered to make sure optimum efficiency and cost-effectiveness. A vendor that uses a vast option of undercarriage components for various heavy equipment brands and designs can be useful as it gives a lot more options to satisfy find out here now certain needs.

Moreover, evaluating the vendor's consumer solution and assistance is crucial. A provider that uses exceptional customer care, quick response times, and technological aid can aid decrease downtime and make sure smooth procedures. Expense is also a considerable factor to think about; nonetheless, it must not be the single component. When choosing the right undercarriage provider for heavy equipment, balancing integrity, cost-effectiveness, and top quality is vital. By very carefully reviewing these factors, you can select a provider that meets your needs and contributes to the reliable efficiency and upkeep of your hefty machinery.

Maintenance Tips for Extended Lifespan

To ensure a prolonged life-span for hefty equipment undercarriage components, carrying out an aggressive upkeep routine is important. Consistently inspecting undercarriage elements such as track chains, idlers, rollers, and gears for wear and tear is vital. Any kind of indicators why not try this out of damages or excessive wear need to be without delay dealt with to avoid more deterioration and prospective failures. Furthermore, maintaining the undercarriage clean from dust, debris, and corrosive products can substantially prolong its life-span. Greasing moving components according to manufacturer recommendations helps in reducing rubbing and avoid premature wear. Keeping an eye on track tension and alignment is likewise vital to avoid unequal endure the undercarriage components. Investing in high quality undercarriage components from reliable providers is just as essential for ensuring longevity. By adhering to these maintenance suggestions diligently, heavy machinery proprietors can maximize the performance and durability of their undercarriage parts, ultimately lowering downtime and functional prices.

Verdict

Finally, top quality undercarriage components are essential for the efficient procedure of heavy equipment. Prompt replacement of worn components can prevent pricey downtime and keep ideal performance. Picking a dependable supplier and adhering to appropriate maintenance practices are essential to guaranteeing the expanded life expectancy of undercarriage parts. By addressing typical try this website wear issues and buying high-grade parts, hefty equipment operators can optimize productivity and decrease maintenance costs.

Extreme wear and tear on undercarriage parts of heavy machinery can lead to considerable functional challenges and enhanced maintenance expenses. Regular examinations, proper maintenance, and prompt substitutes of worn undercarriage parts are vital to minimize these usual wear troubles and make certain the optimum performance of hefty machinery.

A supplier that provides a broad option of undercarriage parts for various heavy equipment brand names and versions can be helpful as it offers extra choices to satisfy specific demands.

By complying with these maintenance suggestions carefully, heavy machinery owners can enhance the efficiency and toughness of their undercarriage components, ultimately reducing downtime and functional expenses.

Report this page